ENGINEERED WOOD SURFACES: CLASSIFICATION, ADVANTAGES, DISADVANTAGES, AND APPLICATIONS

Engineered wood surfaces play a crucial role in modern interior design due to their ability to provide superior aesthetics and protection. Developed using advanced technology, these materials not only protect surfaces but also enhance their visual appeal. So, the question is: what exactly are engineered wood surfaces?

This article provides information on the concept of engineered wood surfaces, common surface types currently available, and their practical applications. Through this, readers will gain a comprehensive understanding of the characteristics and advantages and disadvantages to make informed choices about the appropriate surface type for their design space.

CONCEPT OF ENGINEERED WOOD SURFACES

The surface coating of engineered wood is a specialized layer, processed and pressed tightly onto the surface of engineered wood panels such as MDF (Medium Density Fiberboard), MFC (Melamine Faced Chipboard), HDF (High Density Fiberboard), Plywood, and other types of laminated or artificial wood.

In other words, the surface coating is the outer layer, and the core of the engineered wood is the inner layer. This surface coating can be Melamine, Laminate, Acrylic, or other types of coatings. Regardless of the material, the main function of the surface coating is to protect the wood core from environmental factors, enhance aesthetics, and increase the lifespan of products made from engineered wood.

The role of the surface coating of engineered wood:

Protection and Enhanced Durability

- While the core of the engineered wood panel supports the entire structure, the surface coating acts as a protective shield, increasing the lifespan of the core.

- It prevents environmental impacts such as sunlight, humidity, water, temperature, and dust. It limits deformation, decay, and blistering.

- In short, the surface coating of engineered wood is not only a supporting feature but also creates a strong bond with the core, enhancing durability and preventing damage from environmental factors.

Aesthetics

- Engineered wood surfaces not only protect and extend the product's lifespan but also excel in providing high aesthetic value.

- Through a specialized pressing process, the surface coating enhances aesthetics, creating modern interior design styles.

- Meeting market demands and offering a wide range of choices for consumers in the field of interior design and manufacturing.

Scratch, Chemical, and High Temperature Resistance

- The surface coating on engineered wood panels boasts impressive impact resistance, thanks to its multi-layered structure and strong bonding between its constituent components.

- The high-pressure and high-temperature pressing process creates a robust structure, increasing product durability and improving resistance to physical impacts.

- This combination makes engineered wood an ideal choice for modern interior design and construction.

- In addition, the engineered wood surface is designed to be chemically resistant and able to withstand high temperatures, increasing its applicability in demanding environments.

- This characteristic not only protects furniture from chemical damage but also ensures durability and safety during use.

- This makes engineered wood suitable for the stringent requirements of modern workspaces and living spaces.

Diverse Choices

- The diversity of designs, surface textures, and superior features of coatings such as Melamine, Laminate, Veneer, Acrylic, PU paint, and UV coatings have made them the optimal solution for the furniture industry.

- These coatings not only meet aesthetic criteria but also offer high durability.

- Thanks to these characteristics, the coatings contribute to creating modern, luxurious living spaces and meet the personalized needs of customers.

Environmentally Friendly

- Industrial wood surface coatings are environmentally friendly, contributing to environmental protection.

- Industrial wood surfaces are often produced from recycled materials, reducing the pressure on natural forests.

- Using industrial wood coatings minimizes waste thanks to more efficient production processes.

- Strict control of quality and environmental standards.

5 COMMON ENGINEERED WOOD SURFACES YOU SHOULD KNOW

1. Melamine-coated wood surface

Melamine surfaces, also known as melamine sheets or melamine-coated sheets, are engineered wood surfaces widely used in the furniture manufacturing industry. This engineered wood coating is typically made from decorative paper impregnated with specialized melamine resin. This resin offers excellent heat resistance, moisture resistance, scratch resistance, and abrasion resistance, protecting the underlying wood surface and extending the product's lifespan. Melamine coatings are commonly applied to the surfaces of various engineered wood panels such as particleboard, MDF, HDF, plywood, and WPB.

Diverse Colors and Patterns

Melamine-coated engineered wood surfaces are designed with a rich variety of colors, wood grain, and patterns, offering high aesthetic appeal and reflecting its versatility in interior design. This richness allows designers and consumers to easily choose products that suit their individual needs and tastes, from minimalist modern spaces to luxurious classic styles.

Thanks to its ability to realistically reproduce natural wood grain and vibrant colors, melamine coatings not only enhance the aesthetic value of furniture but also create a harmonious and impressive living space. In this way, melamine coatings become an optimal choice for those seeking a combination of functionality and beauty in interior design. Furthermore, modern printing technologies such as An Cuong's EIR printing technology create unique, raised wood grain patterns, providing a distinctive experience.

Smooth Surface

Melamine sheets are designed with a smooth, flat surface, free from imperfections or roughness, resulting in a uniform and aesthetically pleasing finish. The refined surface texture enhances the tactile feel and improves the overall aesthetic value of furniture. This perfect surface structure also allows the product to easily blend with various design styles, meeting the diverse needs and preferences of consumers.

Easy to Clean and Quick Installation

The melamine surface layer offers convenience in cleaning and allows for quick and efficient production and installation. The ease of cleaning stems from the smooth surface structure, preventing dust and stains from adhering. This not only reduces the time and effort required to maintain the product's cleanliness but also ensures that the surface retains its original aesthetic appeal.

Furthermore, the manufacturing and application process of melamine coatings is designed to optimize production time. Melamine sheets are the top choice for furniture manufacturers in creating high-quality products in a short time.

Affordable Price

Compared to other materials in the furniture industry, melamine not only meets the needs for durability and functionality but also offers cost savings for consumers. The application of melamine sheets in furniture production not only helps minimize production costs but also optimizes economic efficiency for manufacturers.

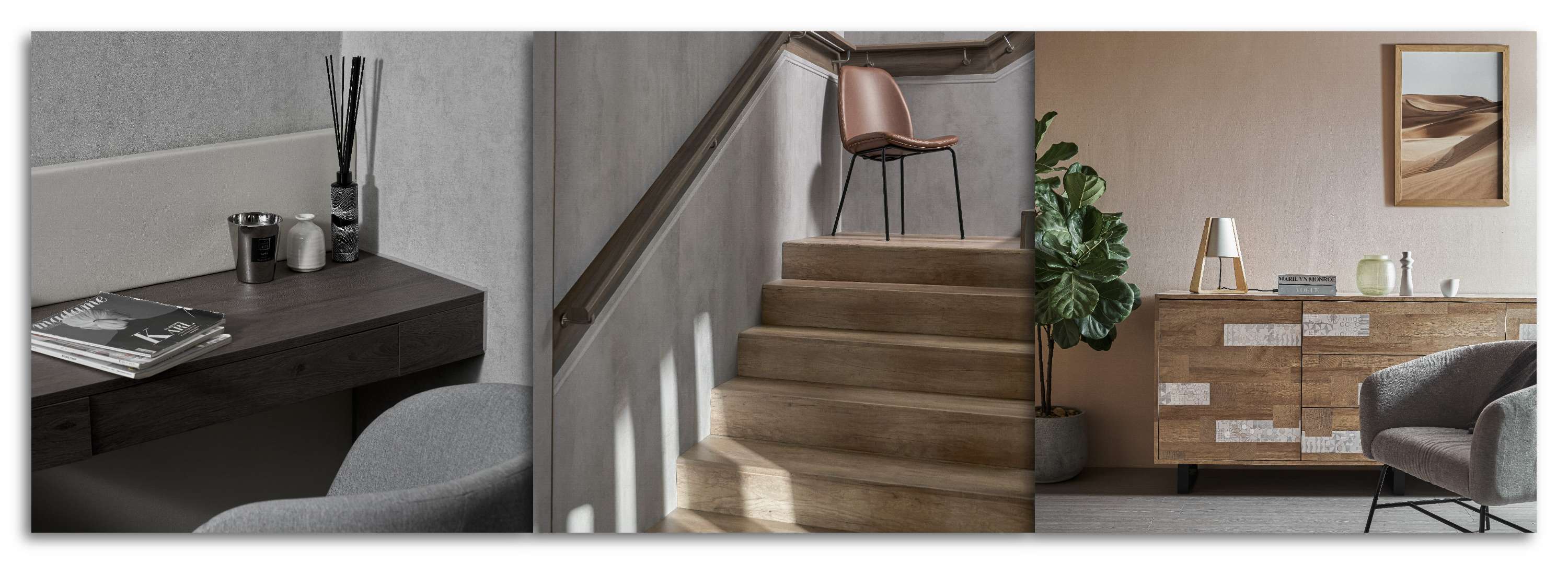

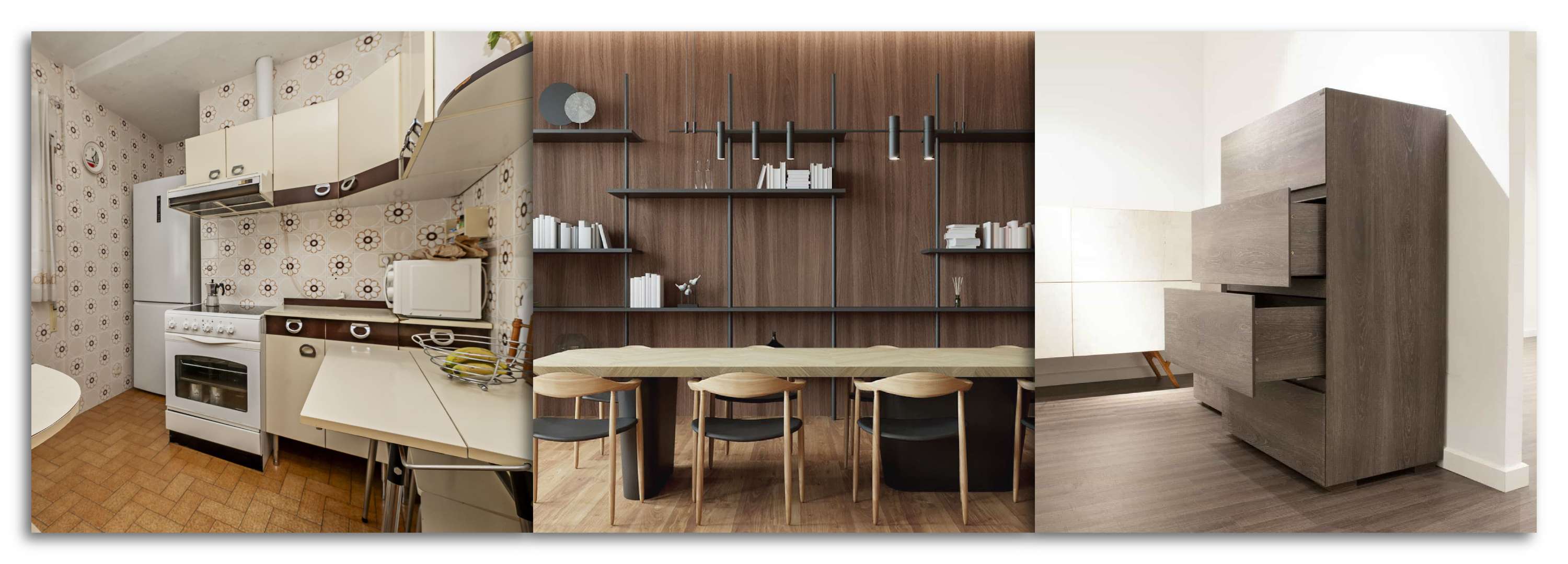

Applications

Melamine-coated engineered wood surfaces are not only distinguished by their superior properties but are also an ideal choice for residential buildings, apartments, schools, hospitals, supermarkets, offices, children's furniture, doors, flooring, and various other construction projects. The image below illustrates the diverse applications of melamine-coated engineered wood in various constructions.

2. Laminate engineered wood surface

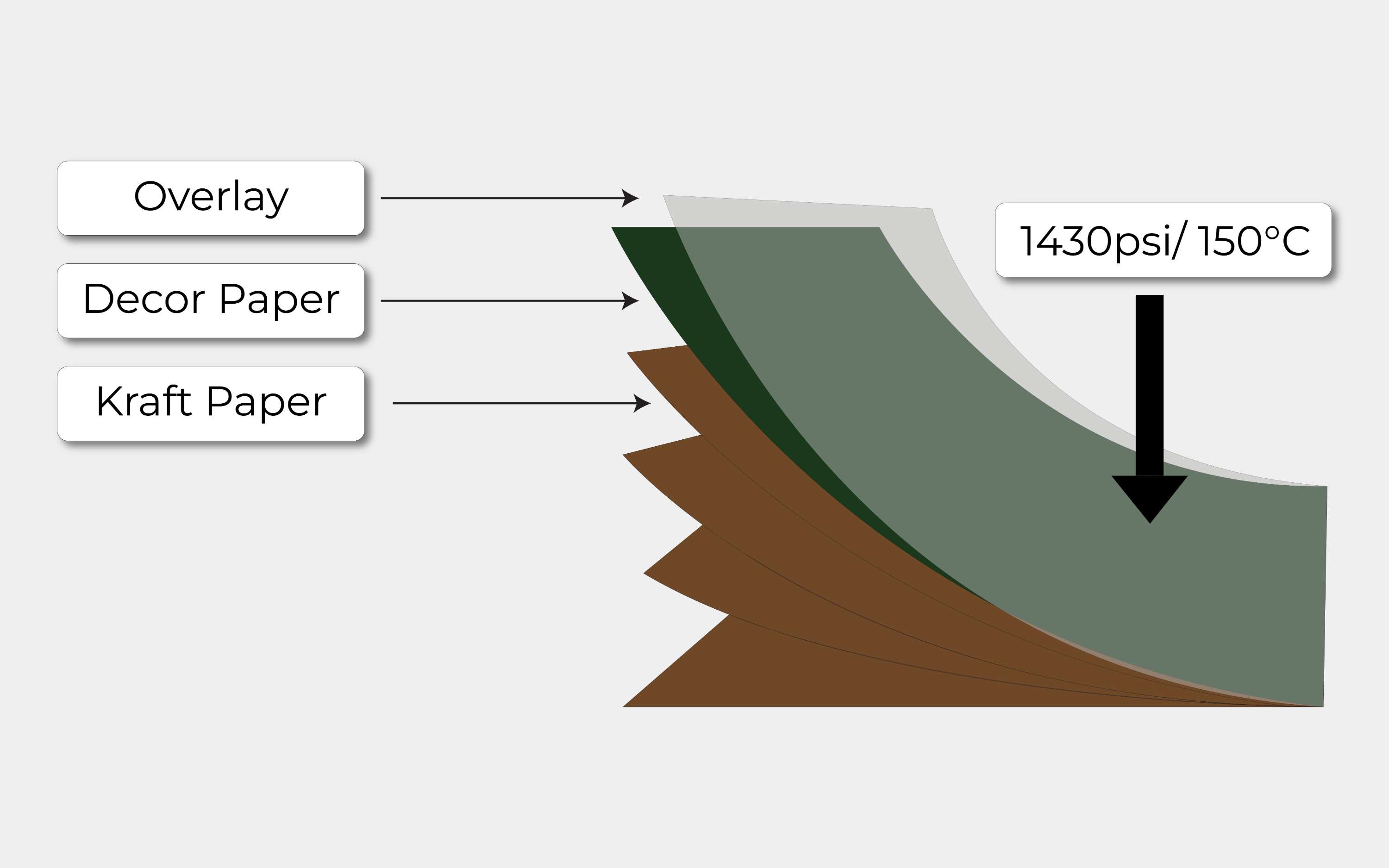

Laminate surfaces, also known as HPL (High Pressure Laminate), are engineered wood surfaces with a complete three-layer structure, offering high durability and aesthetic appeal. The structure of HPL laminate consists of three main layers: a base paper layer (Kraft Paper), decorative paper, and an overlay layer, arranged from bottom to top in a clear order with specific roles. Each structural layer serves a different purpose.

The protective overlay layer prevents scratches and protects the color and decorative patterns from external damage.

Decorative paper, containing patterns, wood grain, or custom colors, enhances the aesthetics and style of the product.

The base paper (Kraft paper) acts as a foundation, providing durability and stability to the entire surface.

The combination of these three layers creates a laminate surface with superior durability and aesthetics, making it a popular choice in modern interior applications.

High Scratch Resistance

Laminate surfaces have become the preferred choice for interior surfaces requiring superior strength and abrasion resistance. This engineered wood surface has a structure consisting of three distinct layers, including a special overlay layer for effective scratch resistance. The combination of these layers gives the laminate panel significant durability against mechanical impacts during use.

Impact, Chemical, and High Temperature Resistance

Laminate-coated engineered wood surfaces have high resistance to many common chemicals, including mild cleaning agents and solvents, helping to maintain aesthetics and extend the product's lifespan. This characteristic not only ensures the surface retains its original shine and color but also minimizes the impact of harmful agents, thereby enhancing the material's durability and long-term usability in interior environments.

Durability

Laminate surface coatings stand out with their effective scratch resistance, as well as superior impact and abrasion resistance, providing product durability even under frequent use or pressure from physical impacts. These characteristics not only help maintain the product's original beauty but also extend the material's lifespan, making laminate a superior choice for interior applications requiring high durability and good load-bearing capacity over time.

Diverse Colors and Patterns

Laminate can meet diverse aesthetic and stylistic needs in interior design thanks to its rich variety of colors and wood grain patterns. With laminate, users can choose from many different surface finish options, from sophisticated smooth gloss to natural rough textures. This helps create an interior space that is both luxurious and provides a warm, cozy, and rustic feel for those who appreciate natural beauty. This versatility is what makes laminate one of the top choices for contemporary interior design.

>>> View more: Understanding the difference between Laminate and Melamine: Which one is better?

An Cuong Company currently offers five different laminate product lines to the market, each with its own unique characteristics to meet diverse needs in the field of interior design and construction. These product lines include:

1. Kingdom Laminate: Products with a wide variety of designs, offering diverse choices in colors and wood grain patterns, suitable for projects requiring high aesthetic standards.

2. Lacquered Laminate: Coated with a special paint finish, this product line stands out with its smooth, glossy surface, adding a touch of luxury to modern interior spaces.

3. Compact Laminate: This type of laminate is thick, durable, and highly resistant, often used in environments requiring high durability and moisture resistance, such as restrooms or laboratories.

4. IMO Laminate: Certified by the international IMO standard, this product line is particularly suitable for marine applications due to its fire-resistant properties and compliance with maritime safety standards.

5. Formica Laminate: An Cuong's Formica laminate is a high-end interior design product, distinguished by its superior features and refined aesthetics, meeting the increasingly high demands of the modern interior design market.

6. Kingdom Basic Laminate: a basic product line, offering reasonable prices while still ensuring quality and aesthetics, suitable for small to medium-sized interior projects.

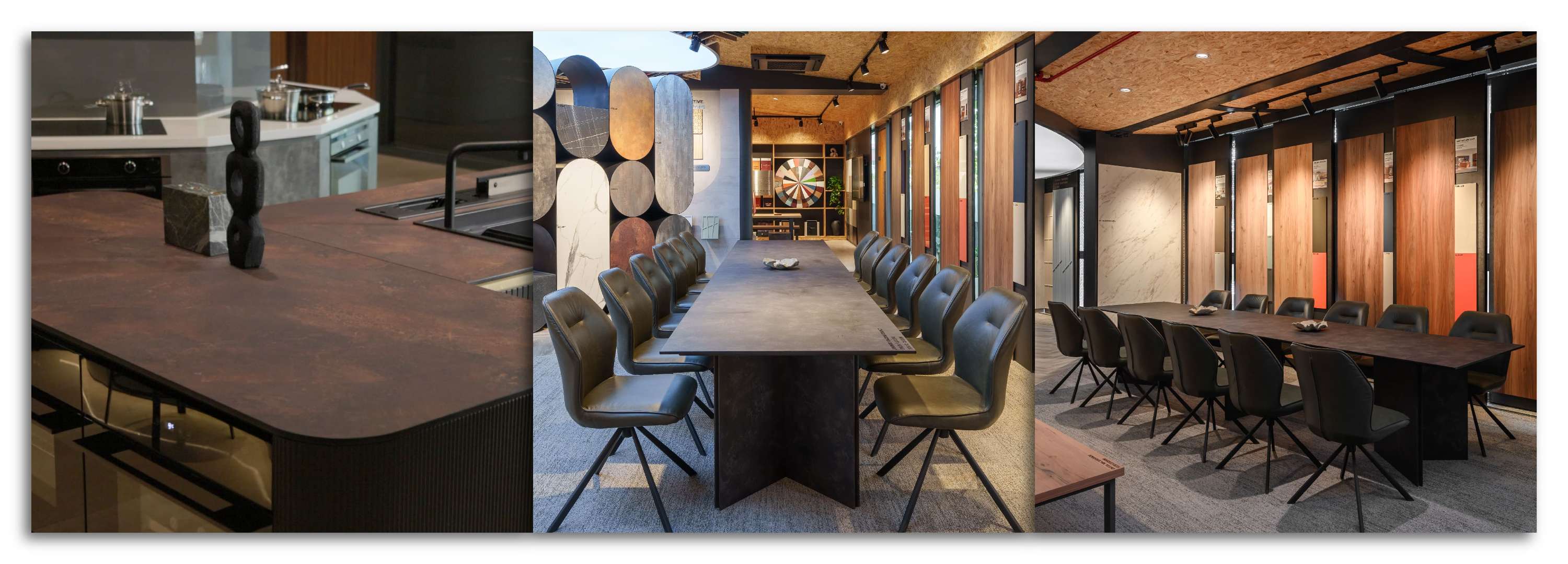

Applications of Laminate Engineered Wood Surfaces

Laminate engineered wood surfaces offer a wide variety of colors and surface types, making them easier to use than melamine panels. Depending on the base wood core material such as PB, MDF, HDF, Black HDF, Plywood, WPB, HPL laminate surfaces are bonded together to create diverse composite materials and flexible applications in manufacturing. This is a key advantage in the versatility of laminate surfaces.

3. Acrylic engineered wood surface

Acrylic surface, also known as High Gloss Acrylic, is an engineered wood surface with a high-grade plastic structure. It consists of an ABS core and an acrylic resin surface layer, professionally known as ABS PMMA (Acrylonitrile-Butadiene-styrene Polymethyl Methacrylate - a flexible plastic composite material). High-gloss acrylic surfaces are commonly produced using extrusion technology, forming sheets measuring 1.2m x 2.4m with a thickness of 0.8–1.4mm.

Smooth and Glossy Finish

Acrylic-coated engineered wood surfaces stand out with their superior smoothness and glossiness, twice as high as conventional painted wood panels. This property provides better light reflection and contributes to a spacious and luxurious feel in interior spaces. Acrylic coating is an ideal choice for projects aiming for a modern design style, where sophistication and elegance are prioritized, enhancing the overall aesthetic value and durability of engineered wood products in diverse architectural spaces.

High Temperature Resistance

Acrylic surfaces have excellent heat resistance, maintaining stable durability even under high temperatures. This characteristic helps the material avoid deformation and warping when subjected to sudden temperature changes in the surrounding environment. Because of this feature, acrylic-coated engineered wood surfaces are used in modern interiors that require high aesthetics, such as kitchen furniture, cabinets, etc.

Easy to Clean

Acrylic surfaces are highly valued for their ease of cleaning and maintenance. This engineered wood surface material allows for quick wiping and removal of dirt. This makes acrylic an ideal choice for interior surfaces that are frequently in contact with users, especially in spaces requiring high aesthetics and maintaining a like-new appearance for a long time.

Creating a sense of spaciousness and depth

Thanks to its outstanding mirror-like surface, acrylic-coated engineered wood surfaces not only offer superior aesthetics but also maximize light utilization in a space. The reflective surface of acrylic not only makes natural light brighter but also contributes to the illusion of a spacious and airy environment. When light shines on it, it is subtly reflected, highlighting interior design elements and adding depth to the space.

This not only creates a pleasant and cozy living environment but also opens up opportunities for more creative designs, where light and shadow interact harmoniously to create a truly impressive spatial experience.

Chemical Resistance

Acrylic surfaces offer effective chemical resistance, preventing corrosion from strong chemicals such as acids or common cleaning agents. This chemical resistance creates a strong protective layer, preserving and extending the lifespan of the underlying wood core. As a result, acrylic-coated products maintain their durability and aesthetic appeal, even in environments requiring strict hygiene and antibacterial properties.

Wide Color Range

Acrylic surfaces offer a wide range of colors with over 100 different options, catering to diverse needs and preferences in interior design. These colors range from modern solid colors, creating a minimalist and elegant look, to metallic shades that provide a sparkling, luxurious feel. In particular, acrylic stands out with its sophisticated wood grain tones, recreating the natural beauty of real wood, bringing warmth and sophistication to interior spaces. This wide range of colors makes Acrylic an ideal choice, suitable for many different interior styles and applications.

Diverse Sizes

The surface dimensions of Acrylic-coated engineered wood are diverse. In particular, this surface coating is available in 2.8m lengths, suitable for interiors requiring oversized heights, facilitating the construction of furniture products that exceed standard height requirements. This size flexibility allows interior designers to be more creative and optimize space effectively, while meeting the stringent demands of the market and consumer needs.

An Cuong's Acrylic-coated engineered wood surfaces come in a rich variety of colors, showcased through three distinctive product lines:

1. Skylux Acrylic: features a superior thickness of 1.4mm. This thickness creates a deep and luxurious visual effect, suitable for modern interior design requirements.

2. High-Gloss Acrylic: a premium, high-gloss material with a wide range of colors, from solid tones to natural wood grain patterns.

3. Arilux Acrylic: Featuring a high-gloss, mirror-like surface and high transparency, Arilux Acrylic creates unique visual effects. It is widely used in high-end projects, including kitchen cabinets, wardrobes, and other furniture products.

Applications

Acrylic engineered wood surfaces are very diverse, with over 100 acrylic colors available, ranging from solid colors, metallic, and faux stone to luxurious wood grain patterns imported from Europe and Australia.

Below is a video summarizing the three most common surface types: Melamine, Laminate, and Acrylic. Please watch to get a general overview and a more visual comparison.

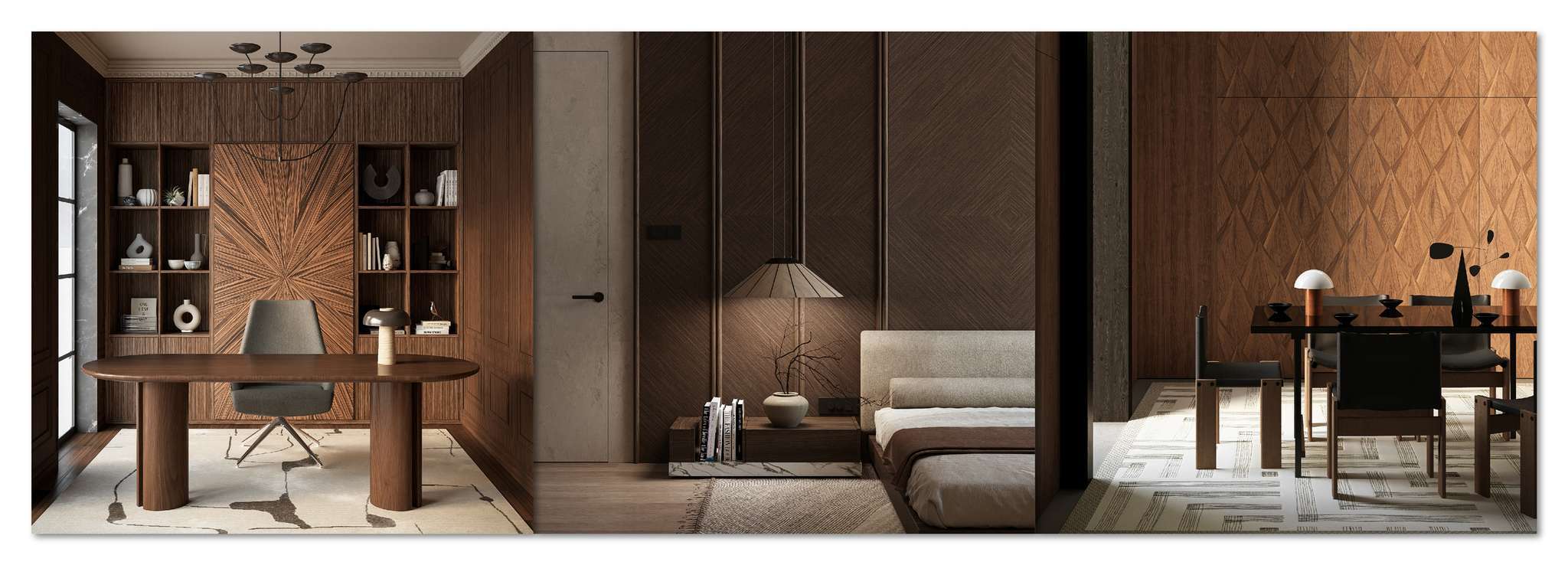

4. Veneer engineered wood surface

Veneer surfaces are an increasingly popular material solution in the interior design and construction industries. Veneer, also known as wood veneer, is made from thin layers of natural wood cut from tree trunks, aiming to create the look and feel of real wood while retaining the benefits of engineered wood. This process not only helps minimize the waste of natural wood resources but also allows for the production of more cost-effective products.

Aesthetics

Veneer-coated engineered wood, inheriting the superior characteristics of natural wood, creates a surface that exudes natural beauty. This surface not only displays unique grain patterns but also boasts a rich variety of colors, contributing to the aesthetic appeal and value of the product. The combination of modern processing technology and the characteristics of natural wood has given veneer-coated engineered wood the ability to almost perfectly replicate the beauty of natural wood, while meeting the needs for sustainability and economic efficiency in modern interior design.

The distinctive aroma of natural wood

The surface of veneer-coated engineered wood stands out not only for its high aesthetic appeal, providing the refined and authentic beauty of natural wood, but also for its subtle, characteristic aroma of woods from natural forests. This distinctive feature is primarily created by the natural oils in the wood veneer, which not only recreate a sense of closeness to nature but also contribute to enhancing the sensory experience of the interior space.

Diverse Colors and Patterns

The colors and patterns of veneer coatings are very diverse, showcasing a wide range of rich shades and forms, which mainly faithfully reflect the natural grain and characteristics of the wood. This diversity not only provides aesthetic appeal but also creates compatibility with many different design styles. The surface of engineered wood covered with veneer, through sophisticated processing, can accurately reproduce natural wood grain, from smooth lines to more complex patterns.

Easy to Process and Fabricate

Veneer-coated engineered wood surfaces are easily processed and fabricated into various styles and designs, meeting the diverse needs of consumers. The combination of aesthetics and durability makes veneer-coated engineered wood surfaces an ideal choice in interior design, especially in modern living spaces.

Applications

In the modern context, veneer-coated engineered wood surfaces have become a popular choice in many living and working spaces, from apartments to company offices. The elegance and natural beauty of veneer not only create a warm feeling but also bring an elegant and sophisticated design style. Therefore, veneer-coated engineered wood surfaces are not simply a physical product but also part of modern interior design trends, demonstrating a harmonious combination of art and technology, aesthetics and practicality.

5. Engineered wood surface with paint finish

Wood surface coatings, often known as "wood varnish" or "wood decorative coating," play a vital role not only in beautifying but also in protecting the surface of engineered wood products and natural wood furniture. Applying this coating enhances the aesthetic appeal of the product by creating diverse finishes in terms of color and gloss, and also significantly protects the wood surface from external environmental factors.

High Gloss

The paint preserves the natural color of the wood after finishing, making it a popular choice in the wood furniture industry. A key feature of this paint coating is its ability to create a smooth, uniform finish, providing not only aesthetic appeal but also effective protection for the wood surface.

Waterproof and Abrasion Resistant

A water-resistant and abrasion-resistant coating is essential for enhancing the durability and usability of wood products in diverse environments. Specifically, the water-resistant coating prevents moisture penetration, a factor that can lead to decay, warping, or cracking of wood when exposed to humid environments for extended periods.

Easy to Clean

The ease of cleaning results in a smooth, water-repellent surface, minimizing the adhesion of dirt, grease, and other contaminants. The ease of cleaning not only benefits users but also contributes to maintaining hygiene and health in living spaces. When surfaces are coated with this type of paint, consumers can quickly and effectively clean them without using harsh cleaning chemicals, thus protecting the environment and personal health.

Applications

The applications of painted engineered wood surfaces in the wood processing and interior design industries are incredibly diverse and extensive, demonstrating their essential role in enhancing the quality and aesthetics of products. In the interior design field, painted surfaces are commonly applied to products such as tables, chairs, cabinets, shelves, and other household appliances.

We have just analyzed five types of decorative material surfaces: Melamine, Laminate, Acrylic, Veneer, and painted surfaces. These are the five most popular surface types that people are interested in. An Cuong is a pioneer in modern manufacturing technology and has thoroughly overcome certain limitations in industrial wood production techniques. As a result, the surface of this brand's industrial wood has become an ideal choice, providing consumers with the most premium experience.

HOW TO CHOOSE ENGINEERED WOOD SURFACES

Choosing engineered wood surfaces isn't just about selecting your preferred color or style; it involves many other factors such as quality, durability, and suitability for your intended use. In my personal opinion, here are some important points to consider to help you make the right decision:

Understand the different types of engineered wood surfaces.

Of course, product knowledge is always my top priority when making purchases. This understanding not only helps consumers make smarter decisions but also ensures the quality and suitability of the product for practical needs. Understanding the characteristics, features, and value of a product also contributes to increased confidence in the selection process, thereby optimizing the shopping experience effectively and responsibly.

Determining the purpose of consumption

Clearly defining your goals when choosing engineered wood surfaces is a step I consider my second most important. This not only affects aesthetics but also ensures the correct use of each surface type in a given environment. Each type of engineered wood surface, from melamine and laminate to acrylic, has its own characteristics and advantages, suitable for specific functional requirements, budgets, and design styles. Therefore, careful consideration in your selection will contribute to creating an optimal and sustainable interior space.

Choose a reputable supplier

Actually, product knowledge and clearly defined goals are the two top points I emphasize. Because when communicating with suppliers, you can identify which suppliers are highly reputable and provide the most accurate information.

Reputable suppliers not only provide high-quality surfaces but also advise on color combinations, standards, and surface maintenance to protect the product from environmental factors. Collaborating with leading suppliers also makes a difference in interior design projects, from durability to long-term aesthetic value.

In addition, I suggest ways to identify reputable suppliers:

1. Ask for recommendations from friends

2. Clear product origin documentation

3. Sales policies

APPLICATIONS OF ENGINEERED WOOD SURFACES

Engineered wood surfaces have become an indispensable element in modern interior design. In the context of interior design, the diversity of colors, patterns, and types of this material not only meets aesthetic requirements but also suits flexible architectural solutions. Engineered wood surfaces offer high economic efficiency during construction, while ensuring durability and resistance to various environmental conditions, thus contributing to the sustainable development of modern living spaces.

In addition to the applications of engineered wood surfaces, at An Cuong, we utilize and transform them into unique material solutions, including:

1. No-line edge banding solution

2. U, J, K, Z, UJ, and UJU handle solutions

3. Shaker, Micro Shaker, and Slim Shaker door solutions

4. 1D, 2D, and 3D profile panel solutions

You can easily find more information about our engineered wood surface solutions at HTTP_CATALOGvi/giai-phap.html

CONCLUDE

Through the above analysis, this article aims to provide readers with a comprehensive and insightful perspective on the common decorative surface materials used in engineered wood today. Specifically, the article focuses on three main surface types: Melamine, Laminate, Acrylic, Veneer, and Paint. By deciphering the characteristics, advantages, and disadvantages of each type, readers can understand their differences and specific applications, from aesthetics to durability and compatibility with various interior spaces.

SOME OTHER FREQUENTLY ASKED QUESTIONS ABOUT ENGINEERED WOOD SURFACES

1. Can engineered wood surfaces withstand moisture or heat?

Engineered wood surfaces are resistant to moisture and heat. The degree of resistance depends on the material of the surface.

2. Can engineered wood surfaces fade?

Of course, prolonged exposure to sunlight will cause the color on the engineered wood surface to fade and lose its original beauty. Therefore, to minimize this, An Cuong suggests using curtains to limit direct sunlight.

3. Can acrylic surfaces be used on all types of engineered wood?

Acrylic surfaces are not suitable for all types of engineered wood and are used as surfaces for MFC, MDF, moisture-resistant MDF, and WPB (Water Proof Board).

4. How to effectively clean and maintain engineered wood surfaces?

To keep your engineered wood surfaces looking bright and new, proper cleaning and maintenance are essential. Here are some helpful tips for cleaning and protecting your engineered wood surfaces for long-lasting durability:

Regular Cleaning

Use a soft, damp cloth to wipe down the engineered wood surface at least once a week.

Removing Dust and Dirt

Use a vacuum cleaner or a soft broom to remove dust and dirt from the wood surface.

Cleaning Stains

Use a clean, soft cloth to clean stains. Additionally, using An Cuong's VuPlex spray enhances shine, reduces scratches, and provides dust resistance.

CONTACT INFORMATION

An Cuong Hanoi Showroom

10 Chuong Duong Do Street, Chuong Duong Ward, Hoan Kiem District, Hanoi.

An Cuong Da Nang Showroom

451 Dien Bien Phu Street, Hoa Khe Ward, Thanh Khe District, Da Nang City.

An Cuong Ho Chi Minh Showroom

279 Nguyen Van Troi Street, Ward 10, Phu Nhuan District, Ho Chi Minh City.

Website:

HTTP_CATALOGvi/lien-he/he-thong-ban-hang.html

Facebook:

https://www.facebook.com/ancuongcompany

Hotline: 19006944

🏠 Components And Accessories For The Furniture Industry

📞 Hotline: 1900 6944

-

#GoAnCuong

-

#AnCuong

-

#woodworking

-

#materials

-

#interior

-

#design

-

#imundex