INDUSTRIAL WOOD MATERIAL BY AN CUONG

Indutrial wood is a popular material widely used in the modern furniture manufacturing industry. In the context of increasing demand for natural wood, unsustainable exploitation of forest resources has posed great challenges to the environment, causing serious degradation of the ecosystem. Engineered wood panels have quickly become a viable alternative, meeting the needs of interior use without negatively affecting natural resources.

So what is indutrial wood, and what makes this material important in modern interior design? Moreover, are engineered wood products safe for the health of users?

WHAT IS INDUSTRIAL WOOD

Industrial wood or industrial boards are artificial wood materials made from wood chips, wood powder or wood chips, bonded together with specialized glue and pressed under high pressure to form large wooden panels. In other words, industrial wood is the use of available raw materials through the natural wood processing process to create panels that not only help create highly uniform wood panels but also create products with high durability and aesthetics. This application contributes significantly to the protection of natural forests and the environment.

Reasons for selecting indutrial wood

Industrial wood, commonly referred to as engineered wood or wood-based panels, encompasses a range of synthetic wood materials composed of wood fibers, particles, or chips that are bonded together using specialized adhesives and subjected to high-pressure compression to form large, stable panels. This advanced manufacturing process repurposes wood by products such as sawdust, shavings, and small wood fragments, generated during the processing of natural timber. By transforming these raw materials into engineered panels, the process not only ensures a high degree of uniformity and structural integrity but also results in products that exhibit enhanced durability and versatile aesthetic qualities.

The stability of engineered wood panels is evident in their ability to maintain both the original color and the structural integrity of the core, despite exposure to environmental factors. A study titled “The Effect of Natural Weathering on Color Stability of Impregnated and Varnished Wood Materials”, conducted by Mugla Sitki Kocman University, highlights that, similar to many other bio-based materials, wood is inherently vulnerable to environmental influences. These factors can lead to gradual alterations in the material’s properties and overall quality over time, thus underscoring the importance of stability in engineered wood applications.

Research conducted by Turkay, Ergun, and Hilmi (2015) demonstrates that light, particularly ultraviolet (UV) radiation, is one of the most significant factors influencing color change in wood during both usage and preservation. The study highlights that the energy present in light, especially UV rays, can induce chemical reactions within the natural composition of wood. These reactions alter organic compounds and internal pigments such as Lignin, Cellulose, and Hemicellulose, resulting in fading or discoloration of the wood. Furthermore, the authors emphasize the critical importance of protective measures to safeguard wood surfaces. They advocate for the application of specialized coatings or paints on both natural and industrial wood panels to mitigate the adverse effects of environmental conditions, such as UV radiation, which can accelerate the degradation process and compromise the material's aesthetic and structural integrity.

“Surface treatment of wood within organic chemicals and impregnation has been suggested among the effective methods to decrease the negative effect of weathering on wood. The application of clear coating is the easiest and most common method for protect-ing wood against natural weathering”

Moreover, engineered wood panels make a significant contribution to environmental protection and serve as a sustainable alternative to conventional materials like cement and steel. A recent study, "Carbon Impact of Engineered Wood Products in Construction", reveals that the construction sector, particularly buildings, is responsible for approximately 39% of global carbon dioxide (CO₂) emissions. This figure highlights the substantial influence of the construction industry on climate change. These emissions are generated not only from the production and transportation of construction materials such as cement and steel, but also from the energy consumption throughout the entire lifecycle of buildings, including their use, maintenance, and eventual demolition. By incorporating engineered wood products, which generally have a lower carbon footprint compared to traditional materials, the construction industry can play a pivotal role in mitigating climate change and promoting more sustainable building practices.

Hongmei, G, Delton, A, Prash, N, and Matthew, A (2021) highlighted that the utilization of engineered wood panels within the construction industry represents a critical strategy in the global endeavor to mitigate and manage the effects of climate change.

“Recent building designs are introducing prom-ising new mass timber products that have the capacity to partially replace concrete and steel in traditional buildings. The inherently lower environmental impacts of engineered wood products for construction are seen as one of the key strategies to mitigate climate change through their increased use in the construction sector.”

Furthermore, the authors examine the potential benefits and associated risks of substituting traditional construction materials with industrial wood. The rising demand for wood may lead to substantial alterations in tree growth patterns, influencing both the volume and intensity of logging activities, which, in turn, can affect the carbon sequestration capacity of forest ecosystems. As market demand for wood escalates, wood prices generally tend to rise, thereby providing economic incentives for investments in sustainable forest management practices. This, in turn, not only fosters an increase in the natural regeneration rates of forests but also contributes to the augmentation of wood reserves, enhancing the overall carbon storage potential of forested areas.

Based on the aforementioned analysis, it can be concluded that the stability and environmental sustainability of engineered wood panels are pivotal in the contemporary context of sustainable construction and development. The inherent stability of these panels not only ensures the long-term durability of structures, thereby reducing maintenance and replacement costs, but also enhances resource efficiency. Additionally, the selection of engineered wood panels significantly contributes to environmental preservation by decreasing reliance on natural wood and mitigating the exploitation of primary forests. This aligns with broader efforts to promote sustainable material usage and reduce the ecological impact associated with traditional timber extraction.

What Defines Quality in Industrial Wood?

The quality of industrial boards is assessed based on six fundamental technical factors, each of which plays a pivotal role in defining the material's properties and long-term durability. These factors are intricately linked to the structural composition of the board and its essential technical characteristics, ensuring that industrial boards fulfill the stringent standards required for use in both interior design and construction applications.

Bending Strength

The bending strength of an industrial wood panel is a primary criterion used to assess the material's capacity to resist deformation under a fixed load applied to its surface. This bending strength index serves as an indicator of the panel's stiffness and structural integrity when subjected to bending forces. Typically, the bending strength is positively correlated with the density of the material, as higher-density boards tend to exhibit superior resistance to bending. This enhanced strength is attributed to the uniform distribution of wood particles and the robust bonding structure formed between the wood fibers during the manufacturing process, which collectively contribute to the panel's overall mechanical performance.

Internal Strength

Tensile strength, also referred to as internal strength, is a critical parameter that quantifies the ability of wood fibers within a panel to be effectively bonded together using adhesive, thereby enabling the board to withstand tensile forces without experiencing delamination or cracking. The internal bond strength is influenced by various factors, including the density and integrity of the bonds between the individual wood elements, the average surface area of the board, and the specific material properties, such as the type of adhesive used and the manufacturing process employed. These factors collectively contribute to the structural stability and load-bearing capacity of the board, allowing it to resist mechanical impacts and maintain its shape when subjected to external forces.

Boards exhibiting higher internal bond strength are less prone to displacement, which directly affects their capacity for fastening and screwing, ensuring the stability and durability of the final product. This enhanced internal bond integrity is particularly beneficial in applications where the product may undergo repeated assembly and disassembly, as it helps maintain the product's structural firmness and overall stability during handling and transportation.

Thickness Swelling

The swelling rate of industrial wood panels is a critical parameter that indicates the material's ability to absorb moisture and its dimensional changes when exposed to high humidity conditions. This factor is fundamental in evaluating the quality and long-term durability of industrial wood products, as it directly influences the stability and performance of the material over time. A lower swelling rate enhances the panel's resistance to issues such as blistering, warping, and deformation, thereby preserving the integrity of the product's shape and surface quality even under challenging environmental conditions.

In regions characterized by high humidity, such as Northern Vietnam with its tropical monsoon climate, industrial wood panels are particularly susceptible to significant swelling, which can lead to a decline in the lifespan and overall quality of interior products. As such, both manufacturers and consumers must carefully consider the swelling rate when selecting industrial wood materials for use in interior applications. To mitigate these risks, high-quality industrial boards are often produced through advanced treatment techniques and the use of moisture-resistant adhesives. These methods are designed to minimize swelling, thereby ensuring the material maintains its durability and functional performance in environments with fluctuating humidity levels.

Density

Density, also referred to as specific gravity, is a critical parameter in the wood industry for assessing the quality and performance of wood boards. It is defined as the mass of wood per unit volume, measured under consistent humidity conditions. Essentially, this index provides an indication of the board’s weight relative to its size.

The density of a wood panel directly influences the overall quality of the product, its intended use, and its suitability for various environmental conditions. A higher density typically correlates with greater resistance to external forces and environmental factors, such as humidity and temperature fluctuations, thereby extending the service life of the board. Since wood is a natural material with hygroscopic properties, it absorbs moisture when exposed to humid conditions. This leads to the expansion of wood fibers, resulting in an increase in both the weight and volume of the wood. As such, in environments with high humidity, such as kitchens and bathrooms, the use of moisture-resistant boards is essential. These boards help mitigate moisture absorption, preventing issues such as cracking, blistering, and mold growth, and thereby ensuring the long-term durability, shape retention, and color stability of interior products.

In both construction and furniture production, the density of wood panels plays a pivotal role in determining the suitability of the material for specific applications. For instance, high-density boards are preferred in areas where superior load-bearing capacity and resistance to mechanical stress are required, such as flooring or structural elements. Conversely, low-density boards are more appropriate for decorative applications or areas where minimal mechanical impact is anticipated. Additionally, the density of a wood board is a key consideration in structural calculations, assisting designers and engineers in selecting materials that provide optimal stability, strength, and safety for construction projects.

Modulus of Elasticity

The modulus of elasticity of wood, also known as the elasticity coefficient, is a technical parameter used to assess the wood's resistance to deformation under the influence of a specified force. This index directly reflects the hardness of wood, representing its ability to maintain its original shape and dimensions when subjected to mechanical stresses such as compression, tension, or bending. Essentially, the modulus measures the degree to which wood can withstand force without undergoing permanent deformation, thereby determining the stability and durability of the wood panels used in applications requiring high load-bearing capacity.

High-quality engineered wood typically exhibits good hardness, with minimal warping or deformation over time, indicating a high modulus of elasticity. The higher the modulus, the more durable and aesthetically stable the wood panels are. Consequently, during the production and application of engineered wood, this index is rigorously calculated and tested to select the appropriate wood types for specific purposes, ensuring compliance with technical requirements and industry standards.

Formaldehyde

Formaldehyde, with the chemical formula CH₂O, is an organic compound that exists as a colorless gas with a distinctive pungent odor. The concentration of formaldehyde in industrial wood refers to the amount of this compound present within the material, typically measured in milligrams per liter (mg/L). In the furniture manufacturing sector, formaldehyde is a key component in the production of specialized adhesives such as Urea Formaldehyde (UF), Melamine Urea Formaldehyde (MUF), and Phenol Formaldehyde (PF). These adhesives are utilized to bond the surface veneer to the wood core, thereby enhancing the mechanical strength and load-bearing capacity of the resulting panels.

The necessity of controlling formaldehyde concentration in industrial wood stems from its potential health hazards. Formaldehyde is a volatile organic compound (VOC) that, when emitted into the air, can cause significant adverse effects on human health, particularly with prolonged exposure to high concentrations. It is known to irritate the respiratory system, eyes, and skin. Chronic exposure, especially in poorly ventilated or enclosed spaces, can lead to severe health issues such as allergic rhinitis, asthma, and even nasopharyngeal cancer. These health risks underscore the importance of regulating formaldehyde emissions to safeguard public health.

Moreover, the unregulated presence of formaldehyde can also have detrimental effects on the material properties and durability of industrial wood products. Excessive formaldehyde content can lead to a reduction in the lifespan of the wood, manifesting in issues such as peeling of the surface coating, distortion of the wood structure, and a decline in the material's load-bearing capacity. These factors can significantly compromise the performance and longevity of the product.

To mitigate these risks, various standards have been established to regulate formaldehyde content in industrial wood. These include recognized safety levels such as Super E0, E0, E1, E2, as well as certifications like EPA and Green Label, which ensure that formaldehyde emissions are kept within safe limits. In conclusion, for industrial wood products to meet quality standards, they must exhibit durability under stress, possess robust internal bonding, provide effective moisture resistance in high-humidity environments, demonstrate uniform wood fiber density, offer flexible elasticity, and maintain low formaldehyde content to ensure consumer safety and product longevity.

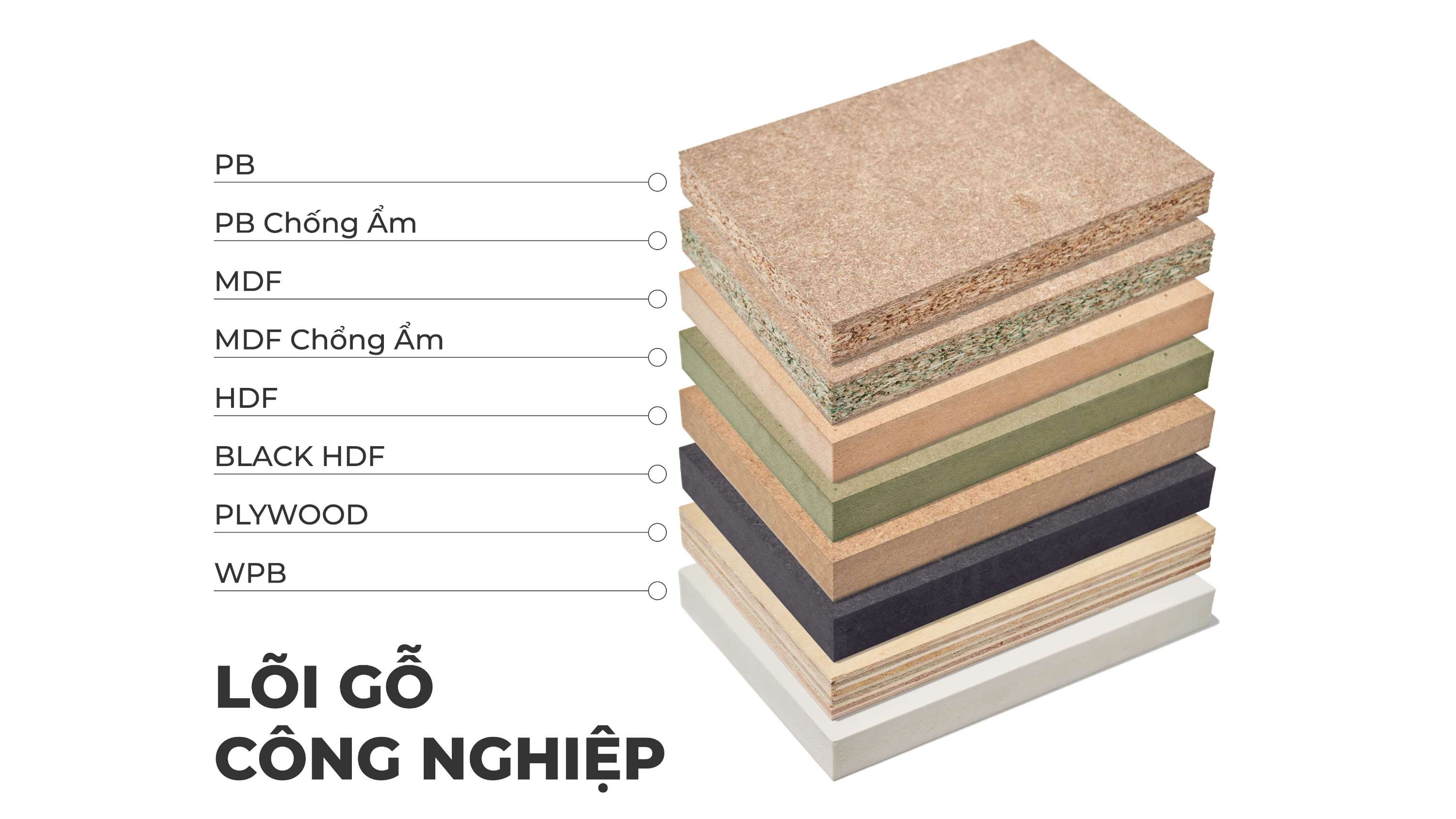

07 COMMON TYPES OF INDUSTRIAL WOOD

Let's take a look at the 7 most popular types of industrial wood and find out why they have become indispensable materials in the furniture industry.

1. Particle Board

Particle Board (PB), also known as chipboard, is a type of industrial wood product that is manufactured by processing wood chips, wood shavings, and wood powder into smaller particles. The production process begins with the mechanical reduction of raw wood materials into uniformly sized chips and fibers, which are then combined with a binding agent, typically an adhesive resin, to form a cohesive mixture. This mixture is subjected to high-pressure and high-temperature conditions in a specialized press, which ensures the formation of stable and durable boards.

The pressing process is crucial, as it helps to bond the particles together and achieve the desired density and strength properties. The resulting particle board can be manufactured to various thicknesses and sizes, meeting a wide range of industry standards and application requirements. Due to its cost-effectiveness, versatility, and ability to be produced from smaller, less expensive wood materials, particle board is widely used in the production of furniture, cabinetry, and other interior applications.

Additionally, the physical properties of the finished product, such as its strength, weight, and surface texture, can be further enhanced through post-processing treatments, such as veneering or lamination, to meet specific design and functional needs in the furniture and construction industries.

02 types of particle board core:

Particle board: wood board produced according to normal standards, not moisture resistant

Moisture-resistant particle board: also known as green core board is standard particle board mixed with additives to increase the bonding strength between wood fibers, good load-bearing capacity and moisture resistance.

MFC, or Melamine Faced Chipboard, refers to a type of particle board that is laminated with a Melamine plastic surface. MFC boards exhibit a broad range of applications, particularly in the construction of office furniture, residential homes, luxury apartments, hospitals, schools, and children's furniture, due to their durability, versatility, and aesthetic appeal.

Currently, 80% of wooden furniture on the market utilizes Melamine Faced Chipboard (MFC) due to its cost-effectiveness, diverse color options, and modern, versatile applications. In the context of Vietnam’s climate and indoor conditions, furniture made from MFC boards can maintain its quality and have a lifespan of 10 to 15 years.

Advantages

- Low production cost, making it suitable for a wide range of customer segments.

- Simple production process that does not require significant labor input.

- Lightweight, making industrial wood chipboard easy to construct and install.

- Large surface area of particleboard, which is ideal for decorative coatings or laminates.

- Due to its structure of small wood pieces, MFC offers durability and hardness.

Disadvantages

- Limited load-bearing capacity, making it unsuitable for heavy-duty applications.

- The edges of the board are highly susceptible to chipping when exposed to external forces.

- Relatively shorter lifespan compared to other materials.

- Poor water resistance, making it prone to blistering under exposure to moisture.

2. Medium Density Fiberboard

MDF (Medium Density Fiberboard), is produced from wood chips, branches, and other wood by-products. These materials are initially broken down into small pieces using specialized machinery, and then processed into fine cellulose wood fibers. The fibers undergo a cleaning process in which impurities, such as plastic and minerals, are removed. Following this, the wood fibers are mixed with various additives, including glue, cellulose powder, adhesive, paraffin wax, wood preservatives, and inorganic fillers.

Similar to Melamine Faced Chipboard (MFC), MDF Laminate is widely utilized in the production of office furniture, residential homes, luxury apartments, hospitals, schools, and children's furniture. Due to its smooth, flat surface, MDF Laminate is well-suited for applications requiring higher technical specifications, particularly for decorative surfaces that demand high gloss and smoothness. This material ensures the achievement of optimal visual effects and is highly adaptable for drilling, painting, and other finishing processes.

Advantages

- No warping or shrinkage: Due to the consistency in its structure, MDF (Medium Density Fiberboard) exhibits minimal warping or shrinkage over time.

- Smooth and flat surface: The uniformity of the material contributes to a smooth, even surface that enhances the aesthetic appeal and usability of the product.

- High-quality production process: The advanced manufacturing techniques employed in producing MDF boards ensure consistent quality throughout, with minimal variation between products.

- Versatility in interior applications: MDF boards are widely utilized in a variety of interior design products due to their adaptability and ease of use in various applications.

- Cost-effective alternative: MDF provides an economical substitute for natural wood, offering similar appearance and functionality at a lower cost.

- Environmental benefits: The use of MDF helps conserve natural forests by utilizing wood fibers from alternative sources, contributing to sustainability efforts in the woodworking industry.

Disadvantages

- Poor water resistance: MDF boards exhibit limited resistance to moisture, which can lead to swelling or damage when exposed to water.

- Lack of flexibility: Unlike some other materials, MDF lacks the inherent flexibility required for certain applications, limiting its versatility in some contexts.

- Limited carving capabilities: The dense composition of MDF makes it unsuitable for intricate carvings or the creation of complex patterns, restricting its use in detailed decorative work.

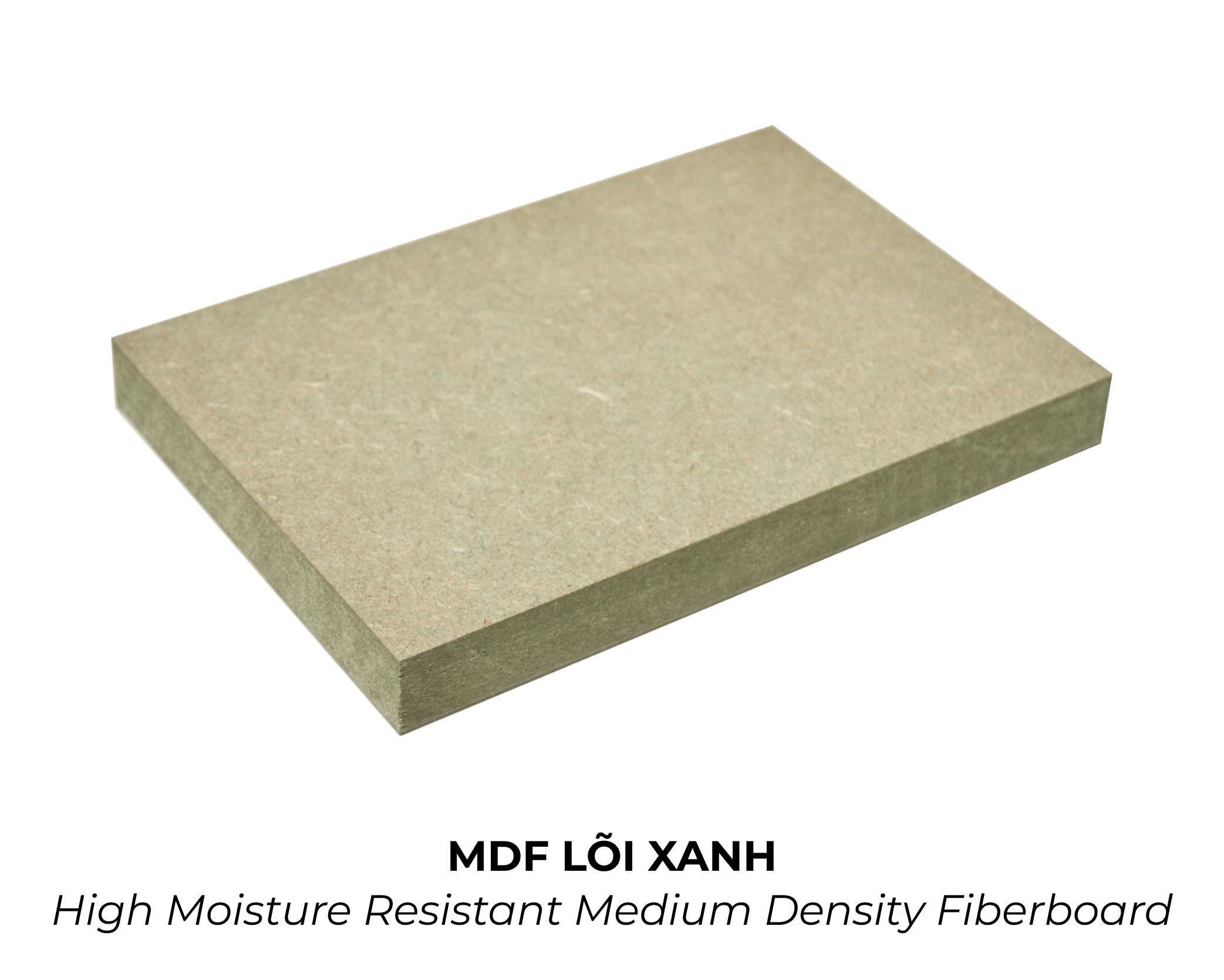

3. Moisture Resistant Medium Density Fiberboard

Moisture Resistant Medium Density Firberboard also known as green core board, is a type of panel commonly used in the furniture industry, particularly in environments with high humidity. The term "green core" refers to the distinctive green coloration of the wood pulp, which serves as an indicator to differentiate it from standard MDF. It is important to note that the intensity of the green color does not correlate with the material's moisture resistance. Like MDF, green core wood is produced from medium-density wood fibers, which are bonded using moisture-resistant MUF (Melamine Urea Formaldehyde) adhesive. Essentially, green core board can be considered an enhanced version of MDF, offering superior moisture resistance and durability. As a result, it significantly reduces the risk of blistering or warping, thereby increasing the overall longevity and performance of the final product.

Advantages

- High moisture resistance of green core MDF industrial board, suitable for Vietnam's climate

- High stability, no shrinkage

- Green core MDF has high durability, up to 10-15 years

- Similar to MDF, the green core board has a smooth, flat surface, convenient for pressing or painting the surface

- High durability and longevity thanks to its tight structure

- Easy to cut or drill

Disadvantages

- Green core MDF is not water resistant and is prone to swelling

- Like MDF, the flexibility of green core is limited

- The cost is higher than other types of industrial wood

4. High Density Fiberboard

High-Density Fiberboard (HDF) is an industrial wood material composed of small wood fibers, which are bonded together using adhesives and compressed under high pressure to form boards with significant hardness and density. Renowned for its exceptional durability and load-bearing capacity, HDF has become a widely used material in the furniture manufacturing industry, particularly in products requiring smooth surfaces and high hardness, such as wooden flooring, doors, and wall panels. The smooth and flat surface of HDF boards enables them to meet stringent technical specifications, especially in applications demanding high gloss and smoothness. This makes HDF an ideal choice for decorative surfaces, as it enhances the aesthetic quality and supports precise processes like drilling, shaping, and painting.

Advantages

- HDF wood panels are flat and smooth, without wood chips or tiny voids and are convenient to cover the surface

- High compression ratio helps HDF withstand force well, not deformed or cracked when impacted

- High hardness and ability to withstand large loads

- Low HDF expansion limits blistering when exposed to high humidity environments

- HDF panels have sound and heat insulation capabilities

Disadvantages

- Higher cost than MDF or green core MDF

- Limited flexibility, not suitable for manufacturing curved furniture

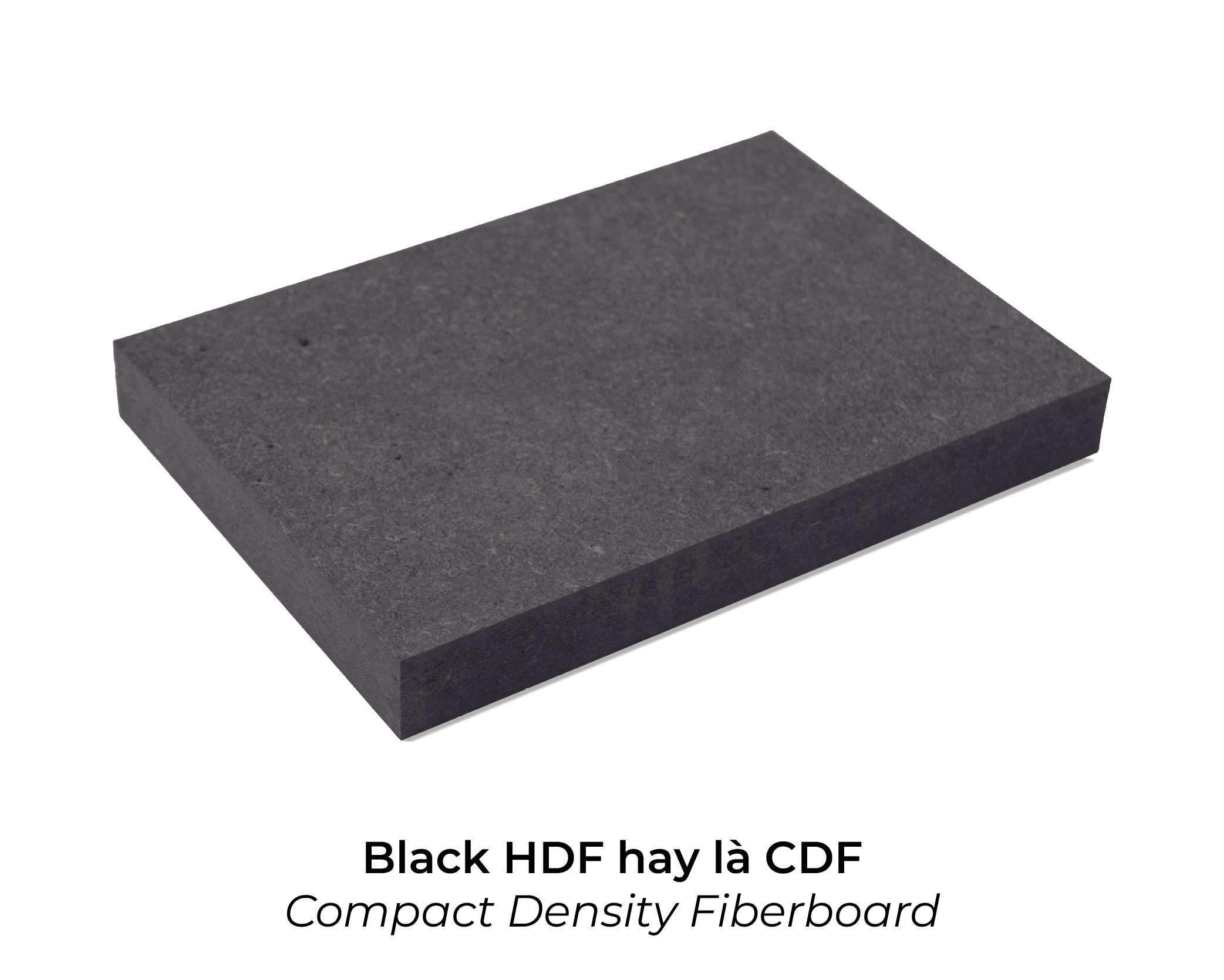

5. Compact Density Fiberboard

CDF wood (Compact Density Fiberboard), an abbreviation for "Compact Density Fiberboard," is an industrial wood material characterized by its high fiber density, akin to HDF (High-Density Fiberboard), but with a greater pressing density and compression mass. Essentially, CDF wood can be regarded as a variation of Black HDF wood. This material is typically produced by combining small wood fibers with adhesive, which are then subjected to extremely high pressure during the manufacturing process, resulting in boards with enhanced thickness and durability.

CDF boards, or Black HDF wood, are particularly well-suited for applications that require superior moisture and water resistance, such as kitchen cabinetry, partitions, lavatories, restroom walls, coffee table surfaces, decorative wall panels, and intricate cutting equipment. The cost-effectiveness of CDF panels, along with their wide range of available colors and ease of construction using common industrial wood machinery, make them a popular choice in the industry. Notably, the black-dyed core of CDF panels provides a distinct aesthetic advantage, enhancing the visual appeal of decorative cutting details.

The primary distinguishing feature of CDF wood is its remarkable ability to resist moisture and water, a quality highly valued in residential interior applications. To further enhance its durability, CDF boards require only oiling on their edges before they are ready for use in finishing applications.

Advantages

- Like HDF, Black HDF wood has outstanding durability.

- Good moisture resistance, suitable for spaces with high humidity

- Due to its compressed structure and high density of wood fibers, HDF boards are resistant to strong impacts and withstand large external forces

- Smooth flat surface suitable for surface coating, creating diverse and rich products

Disadvantages

- Large weight is not convenient for construction and installation

- Complicated production and superior properties make the price of HDF industrial wood boards very high

- High hardness makes toughness not good and is not suitable for curved products

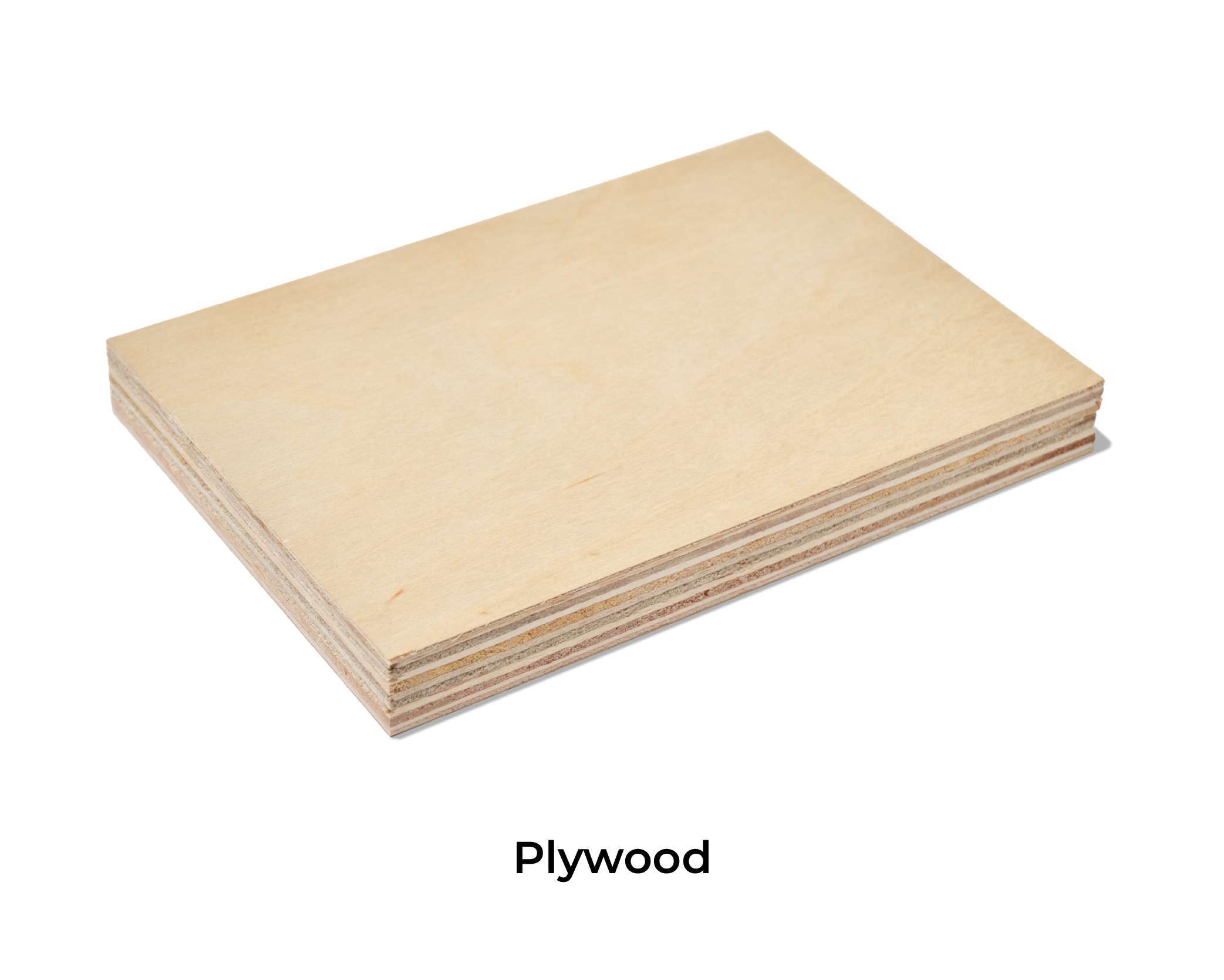

6. Plywood

Plywood, an engineered wood product, is composed of multiple layers of natural veneer that are stacked and bonded together under high pressure using adhesives such as phenol or formaldehyde resins. The veneers are arranged with the wood grain of each layer oriented perpendicular to the adjacent layers, a configuration that significantly enhances the material's strength and durability. This layered structure provides plywood with superior load-bearing capacity, resistance to warping, and long-term stability. Available in various sizes, thicknesses, and with versatile bending properties, plywood is widely employed in construction and interior design, serving applications ranging from formwork and flooring to cabinetry and innovative interior features. Moreover, the longevity and sustainability of plywood contribute to its environmental benefits, enhancing both the product's value and its role in sustainable building practices.

Advantages

- Multi-layer structure and wood grain arrangement, Plywood has good load-bearing capacity and is less prone to warping

- Light weight, convenient for construction and installation

- Plywood has a variety of thicknesses and sizes, suitable for many different applications.

- High-end Plywood boards, when pressed with waterproof glue, can withstand well in humid environments.

Disadvantages

- Complicated production process makes Plywood often more expensive than some other types of industrial wood

- The hardness is very high, so cutting and processing Plywood requires specialized tools.

ADVANTAGES OF INDUSTRIAL WOOD

Engineered wood has many outstanding advantages over natural wood, making it a popular choice in many different interior design applications, especially in furniture and construction. Here are some of the main advantages of engineered wood:

Reasonable price

The process of manufacturing industrial wood, with the maximum utilization of wood chips from the natural wood processing process and the application of modern technology, has created an optimal economic solution compared to the traditional natural wood production method. This is clearly demonstrated through the significant reduction in raw material costs, thereby increasing the competitiveness of products in the market.

High durability and stability

Industrial wood, thanks to modern production processes, has overcome the inherent limitations of durability and stability of natural wood. Advanced processing technologies help this material have superior resistance to warping, shrinkage and termites, ensuring product longevity and quality under different conditions of use

Diversity in designs and colors

Industrial wood is easily covered with surface layers such as melamine, laminate, veneer, acrylic high gloss to create many rich designs and colors, meeting the diverse aesthetic needs of consumers.

Environmentally friendly

Industrial wood production often uses waste wood, wood chips or short-term crops, helping to reduce deforestation and protect the environment. Some recycled materials are used in industrial wood production.

An Cuong Wood Joint Stock Company is a leading manufacturer and supplier of raw materials, solutions and furniture made from industrial wood in Vietnam and the region. In addition to the Green Label – Singapore certification for green, clean, environmentally friendly and user-friendly products, all An Cuong industrial wood products also receive the GreenGuard certification from UL. This is one of the most prestigious certifications in the world for product safety and environmental friendliness.

Industrial wood has uniform size and thickness, making cutting and assembling easier. Industrial wood products are also often designed in a modular style, convenient for installation and replacement.

Easy to construct and install

Industrial wood has uniform size and thickness, making cutting and assembling easier. Industrial wood products are also often designed in a modular style, convenient for installation and replacement.

Good moisture and fire resistance

Some types of industrial wood, such as moisture-resistant MDF or HDF, are specially treated to increase moisture and fire resistance, suitable for areas with high humidity or high safety requirements.

Good sound and heat insulation

With its special structure, industrial wood not only possesses outstanding sound and heat insulation but also brings aesthetic beauty to the space. Thanks to that, this material contributes to creating a quiet, comfortable living and working environment, while saving energy effectively.

DISADVANTAGES OF INDUSTRIAL WOOD

Industrial wood is becoming more and more popular in the manufacturing and interior decoration industry thanks to its many outstanding advantages. However, it also has disadvantages that users need to pay attention to. Here are some of the main disadvantages of industrial wood:

Lower durability than natural wood

Industrial wood is often not as durable and long-lasting as natural wood. Industrial wood is susceptible to damage faster under the impact of strong forces or harsh environmental conditions.

Poor water resistance

Although some types of industrial wood have been improved to be moisture-resistant, most industrial wood is still susceptible to damage when exposed to water for a long time. This reduces the life and aesthetics of the product.

Unable to carve sophisticated patterns

Due to the structure of industrial wood from wood chips and wood chips, the wood grain structure is not as tightly linked together as natural wood. Therefore, industrial wood is not capable of carving and sculpting details for interior products that require sophistication and complexity in design.

Difficult to repair

The uniform structure of industrial wood, although it brings many advantages, limits the ability to repair when damaged. Unlike natural wood, scratches and dents on the surface of industrial wood are often difficult to fix and require replacing the entire wood panel, causing costs and affecting the aesthetics of the product.

Therefore, when damaged, industrial wood is more difficult to repair than natural wood. Scratches, dents or damage often require replacing the entire wood panel instead of just repairing a part.

Weaker load-bearing capacity

The limited load-bearing capacity of industrial wood compared to natural wood poses certain challenges in applying this material to interior products that require high durability. This can lead to a reduction in the lifespan and stability of the product during use.

Design Limitations

Although engineered wood has a wide variety of designs and colors, it is still limited in its customization capabilities compared to natural wood. Unique and complex designs are often difficult to achieve with engineered wood.

In summary, although engineered wood brings many economic and aesthetic benefits, users need to carefully consider the above disadvantages when choosing this material for interior projects.

APPLICATION OF INDUSTRIAL WOOD IN INTERIOR DESIGN

Possessing outstanding advantages, industrial wood is widely used. Below are some common applications:

Living Room Furniture

Engineered wood is effectively used in living room interior design through products such as TV stands, display cabinets, coffee tables, and room dividers. With its ability to create attractive surfaces and a wide variety of colors, engineered wood helps create a modern and cozy living space.

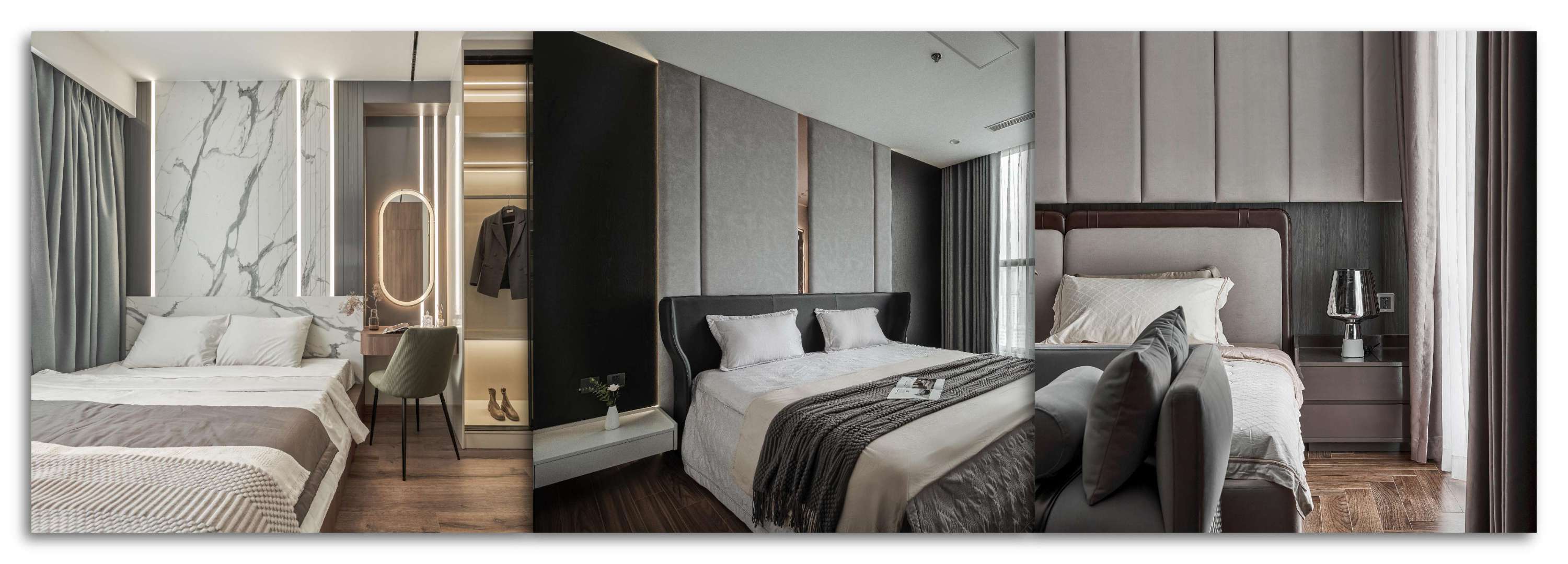

Bedroom Furniture

In bedroom interior design, engineered wood is used to manufacture beds, wardrobes, dressing tables, and bookshelves. Thanks to its high stability and resistance to warping, engineered wood ensures long-lasting durability for furniture in the resting space.

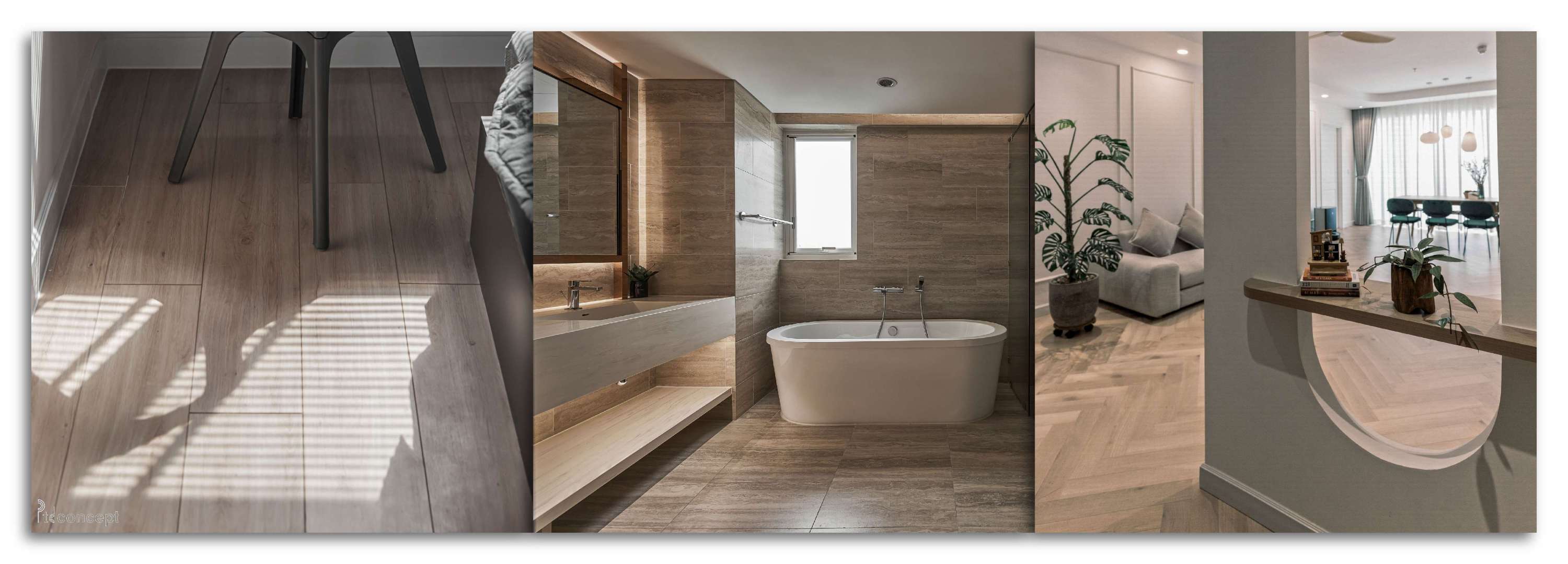

Kitchen Furniture

Moisture-resistant engineered wood such as MDF and HDF is favored in kitchen interior construction, especially for kitchen cabinets, dish racks, and kitchen islands. Its high moisture resistance and ease of cleaning help engineered wood maintain its quality in environments with high humidity and temperature.

Office Furniture

In office spaces, engineered wood is used to manufacture desks, filing cabinets, bookshelves, and partitions. With its good load-bearing capacity and smooth, flat surface, engineered wood creates a professional and comfortable working environment.

Other Applications

Engineered wood is also used in many other fields such as engineered wood flooring, stairs, ceilings, and construction projects. The versatility and diversity of this material open up countless creative possibilities in design.

HOW TO USE AND CLEAN INDUSTRIAL WOOD PROPERLY?

Proper use and cleaning of engineered wood is an important factor in maintaining the beauty and durability of your home's interior. Below are the steps and notes to help you clean and preserve engineered wood effectively:

- Dry immediately when water is spilled on engineered wood furniture.

- Limit direct sunlight on the engineered wood surface

- Use a coaster for hot/cold items - avoid placing them directly on the table top or kitchen top made of engineered wood.

- Use a soft, clean cloth combined with a specialized solution to clean engineered wood surfaces, especially mirror-polished acrylic surfaces. Note: Do not use strong detergents.

- Promptly handle scratches and minor damage.

How to clean indutrial wood: https://www.youtube.com/watch?v=Ya0LTfKkTDw

CONCLUSION

Historically, industrial wood was commonly regarded as a form of artificial or imitation wood, often seen as a substitute for natural timber. However, with the rapid advancements in modern manufacturing techniques and technology, this perception has evolved significantly. In contemporary times, industrial wood has emerged as an optimal material for the modern furniture manufacturing industry, primarily due to its numerous advantages, including cost-effectiveness, aesthetic versatility, and sustainability benefits. The enhanced production processes have allowed industrial wood to closely mimic the appearance and texture of natural wood, while offering greater durability and a more environmentally friendly profile. As such, understanding the different types of industrial wood and their various applications has become crucial for both consumers and designers. This knowledge enables more informed decisions when selecting the most appropriate product that meets specific functional, aesthetic, and environmental requirements, ultimately ensuring that the materials chosen align with both practical needs and modern design trends.

FAQs

1. Experience in choosing industrial wood

An Cuong gives you some important tips that you should keep in mind to ensure that you are choosing to buy quality industrial wood products that reflect the true value of your money. Let's take a look:

Learn about the brand: Learn about reputable industrial wood brands on the market. Consider the brand, brand certifications, product quality certifications, services and feedback from previous customers.

Visit showroom: You should also visit the product showroom to learn more about the sensory aspect and get advice on the product as well as your needs. In addition, the consultant will also advise you on interior solutions to help you have a lot of useful and interesting information to beautify your living space.

Choosing a design and construction consulting unit: In addition to choosing a reputable and branded industrial wood supplier, you should also choose professional interior design and construction consulting units - enthusiastic and thoughtful, with professional knowledge as well as understanding of new materials. This will help you have a neat and modern living space.

Calculate cost and value: Compare the price and quality of the product. Don't just choose the cheapest product and forget about the quality factor. Calculate the ratio between cost and value to ensure that you are investing in the right product.

Check product origin: After the furniture has been manufactured, you can check the color of the material as well as the quality of the product. In addition, major brands will provide value-added invoices, warehouse receipts, you can also check the origin and origin of the goods through these.

Hopefully the above experiences will help you confidently and intelligently choose to buy industrial wood, ensuring that you will get quality products that suit your needs.

2. Can industrial wood be recycled?

Industrial wood is recyclable; however, the process of recycling industrial wood still has outstanding problems such as impurities in the wood, energy and recycling costs are higher than production.

3. Is industrial wood painted on the surface?

Of course, painting the surface of industrial wood not only protects the wood core over time but also increases aesthetics and creates more choices for customers. Commonly coated surfaces include Melamine, Laminate, Acrylic or painted. In addition to coating or painting the surface, industrial wood is laminated on 4 edges with PVC plastic strips to increase the overall beauty of the industrial wood panel.

CONTACT

Showroom An Cuong Ha Noi

No. 10 Chuonng Duong Do, Ward Chuong Duong, Hoan Kiem District, Ha Noi

Showroom An Cuong Da Nang

451 Dien Bien Phu, Ward Hoa Khe, Thanh Khe District, Da Nang City

Showroom An Cuong Ho Chi Minh

279 Nguyen Van Troi, Ward 10, Phu Nhuan District, Ho Chi Minh City

Website: HTTP_CATALOGen/contact/showroom.html

Facebook: https://www.facebook.com/ancuongcompany

Hotline: 19006944

🏠 Components And Accessories For The Furniture Industry

📞 Hotline: 1900 6944

-

#GoAnCuong

-

#AnCuong

-

#woodworking

-

#materials

-

#interior

-

#design

-

#imundex